as an addendum, especially in light of the 1st set of pictures just vanishing, I'll give an update on how i did mine and what i looked like. I went into it over the weekend because i was getting a slight slipping if i aggressively shifted on occasion. and i just wanted to check see how it was doing.

crash bar swing forward and out of way, foot peg bar taken out. already had drained oil:

pulling the bearing out. few things here to note. 1: the most obvious being the flywheel, no longer the auto clutch. this came from motogaga for the wave 125 conversion they sell. while it fit the shaft and the primary gear is fine, etc, note 2 things. 1" the oil hole in the crank that would normally feed the spinner cavity is exposed. I mentioned this above. To rectify this, I drilled out the brass ball in the crank and sleeved the passage with a 6mm od x 3mm id aluminum sleeve to allow oil to pass thru. this is what oils the top-end. IF this was left open the top-end would never get oil. 2: I had to add a 'notch' for the lock tab washer to have something to grab onto, you can see it in the spline area.

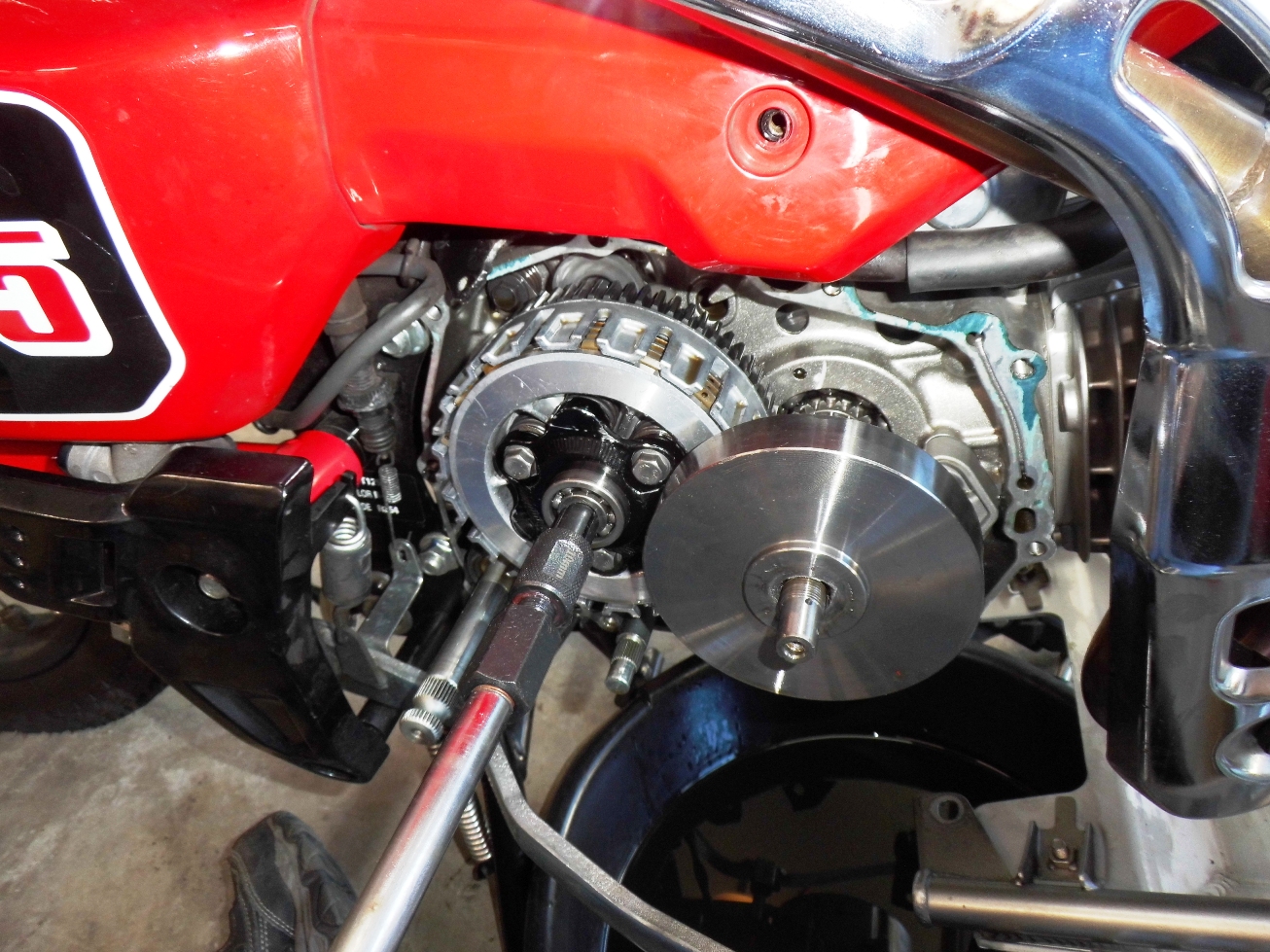

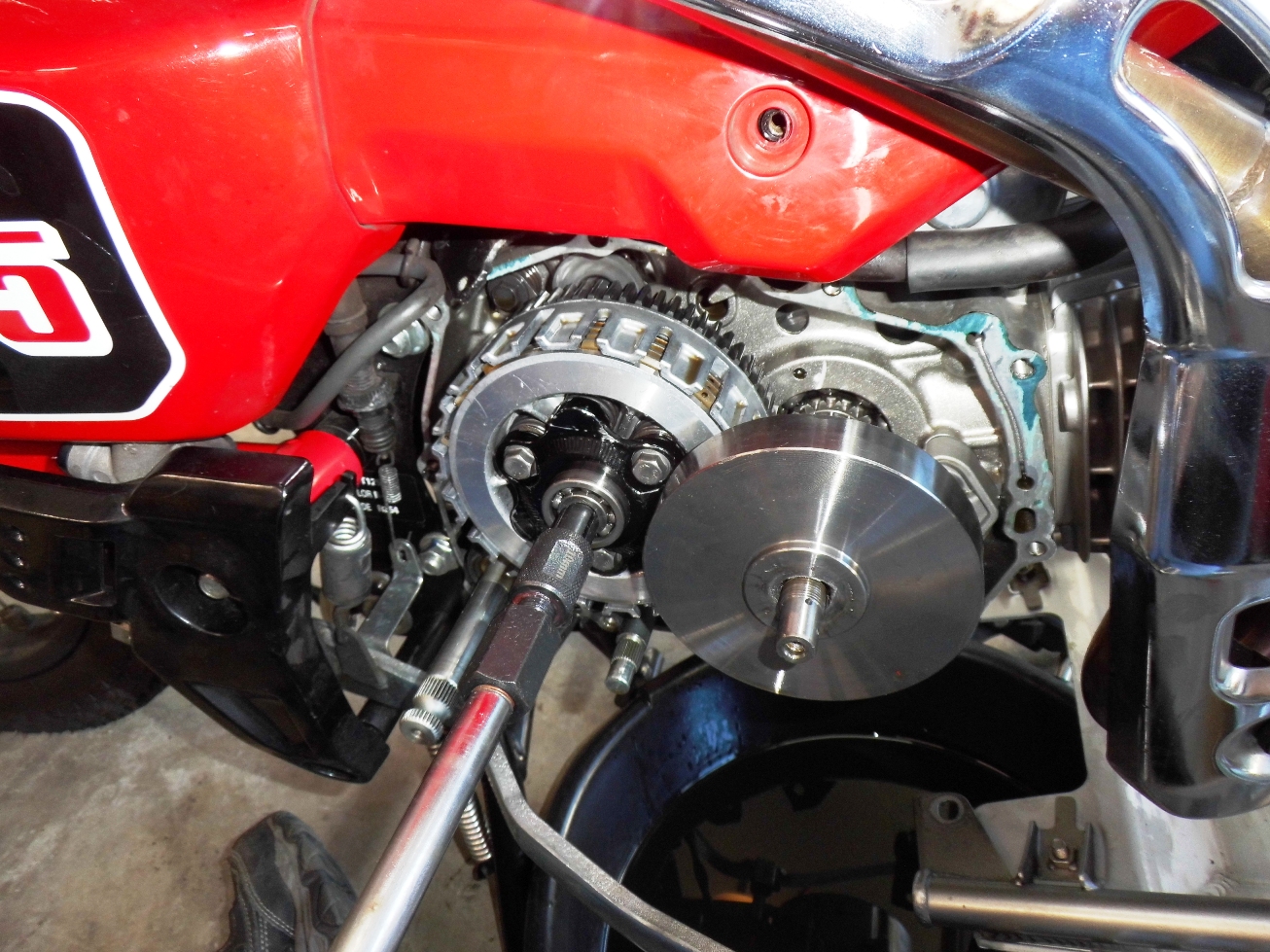

you can see the crank end here as well. note: the clutch assembly and spinner need to go on at the same time. the pint behind this was to set the clutch pack on, and then tighten the pressure plate bolts down with it aligned . you can also see the 'inlet' oil spinner galley hole at the crank splines and the 'outlet' hole further down the shaft as seen above.

i had a few variants of stock and aftermarket clutch parts leftover from the grom stuff, and found this pressure plate backing hub that was a bit thicker on the main plate, but the studs were the same length. this will help preload the clutch discs at rest to give better grip. the stock ct one was about the same as the one on the right. the ct also uses less clutch discs than the grom motors, so you're working with 20% less, which is doable but creates an interesting challenge with the flywheel (and stock centrifugal clutch) reducing the clearance to the clutch basket. (and why i didn't just run a 5 or 6 disc basket).

while i had it out, i took about 12mm off the flywheel, seemed a bit excessive as big as it was. def revs a tad quicker now.

here it is bolted back together. note the bearing is offset out (as it was before) to clear the clutch hub nut due to the shallower basket AND smaller ID required by the grom cover i used.

also installed some aftermarket diamond pattern clutch steels and new frictions i had (takegawa i think? had em forever) and test rode it yesterday, def better. I had well over 1200 miles on the man ual cluthc setup before i went in and it did work well.

and yes, this is hand's down the most convoluted and complicated way to do it, so i don't recommend it. But i do like how it works. IMHO better than welding up the auto clutch of doing a grom crank or lower end swap. (which i do have one and might build a 186 down the road).